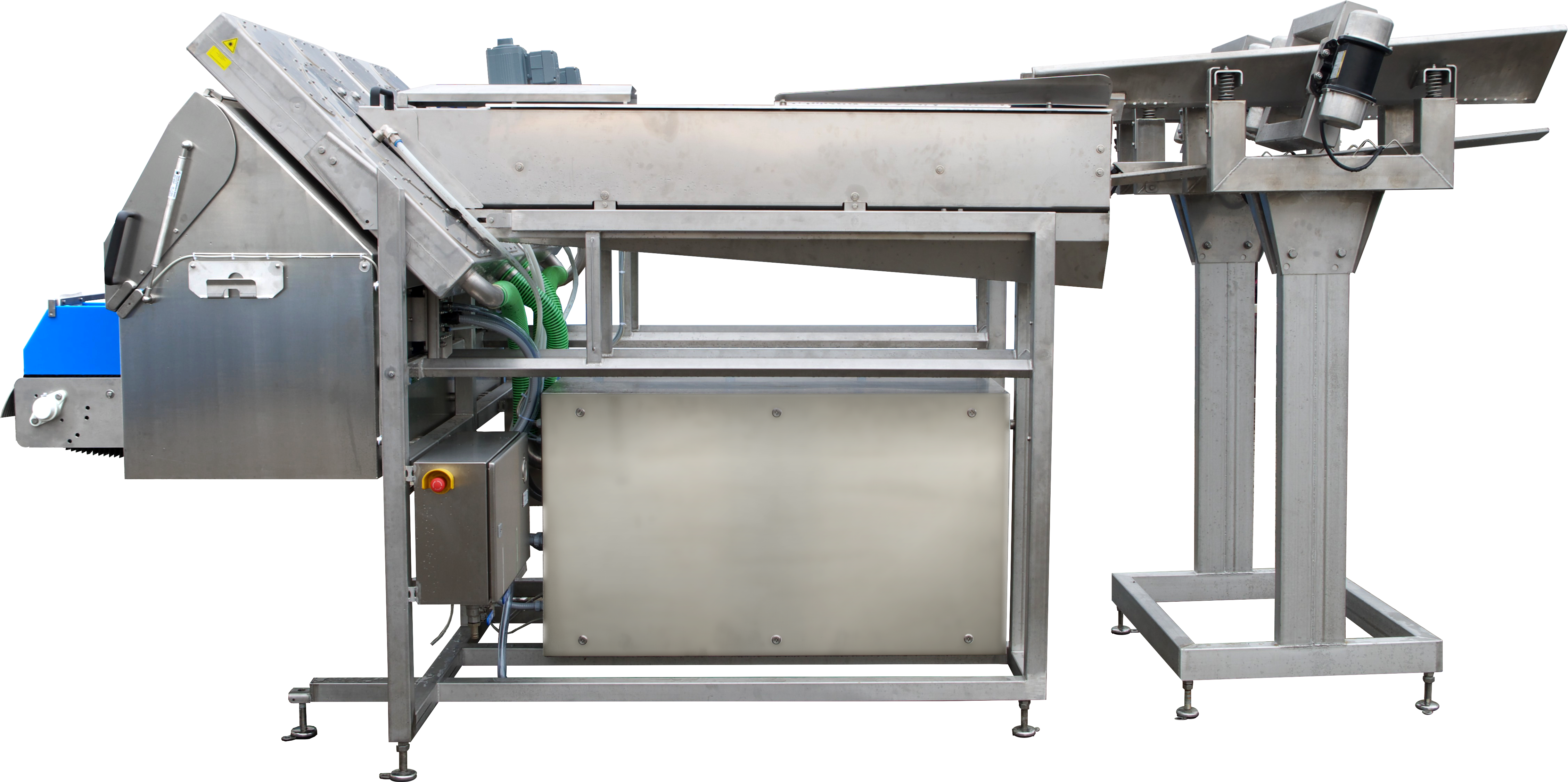

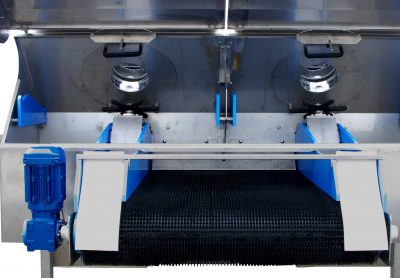

Sorting machine for washed, unpeeled products

Characteristics

20 t/h

is the maximum processing capacity of the AGROSELECTOR® twin arcus.

Capacity depends on product type and size.

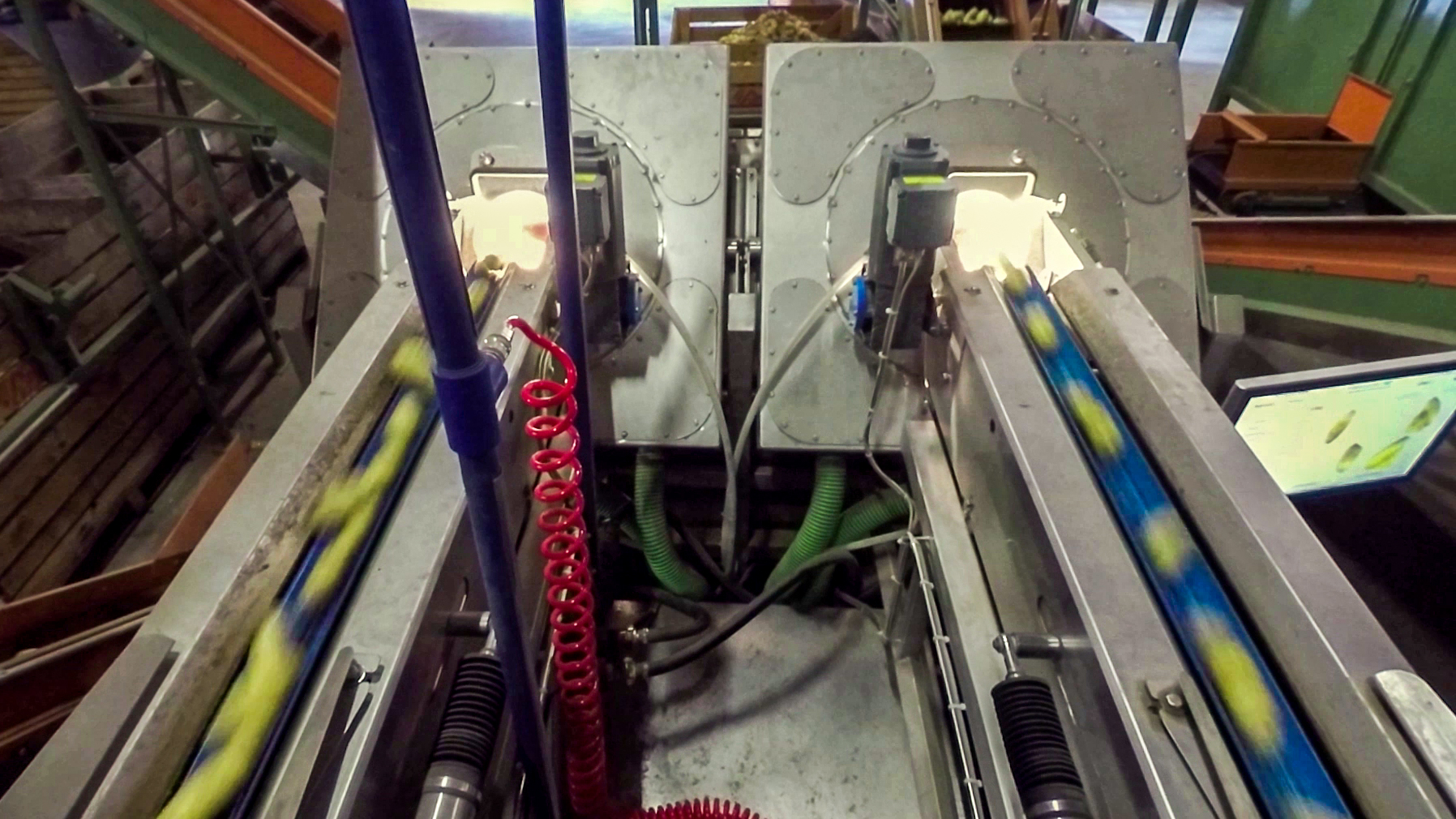

360°

An all-round view makes it possible to capture the entire product surface.

The AGROSELECTOR® twin arcus identifies the following on the product surface:

- Color values

- Contrast differences

- Spots of rot

- Green marks

- Red, brown, and black spots

- Scab, Rhizoctonia

- Foreign objects

The size and external shape of the product are also detected.

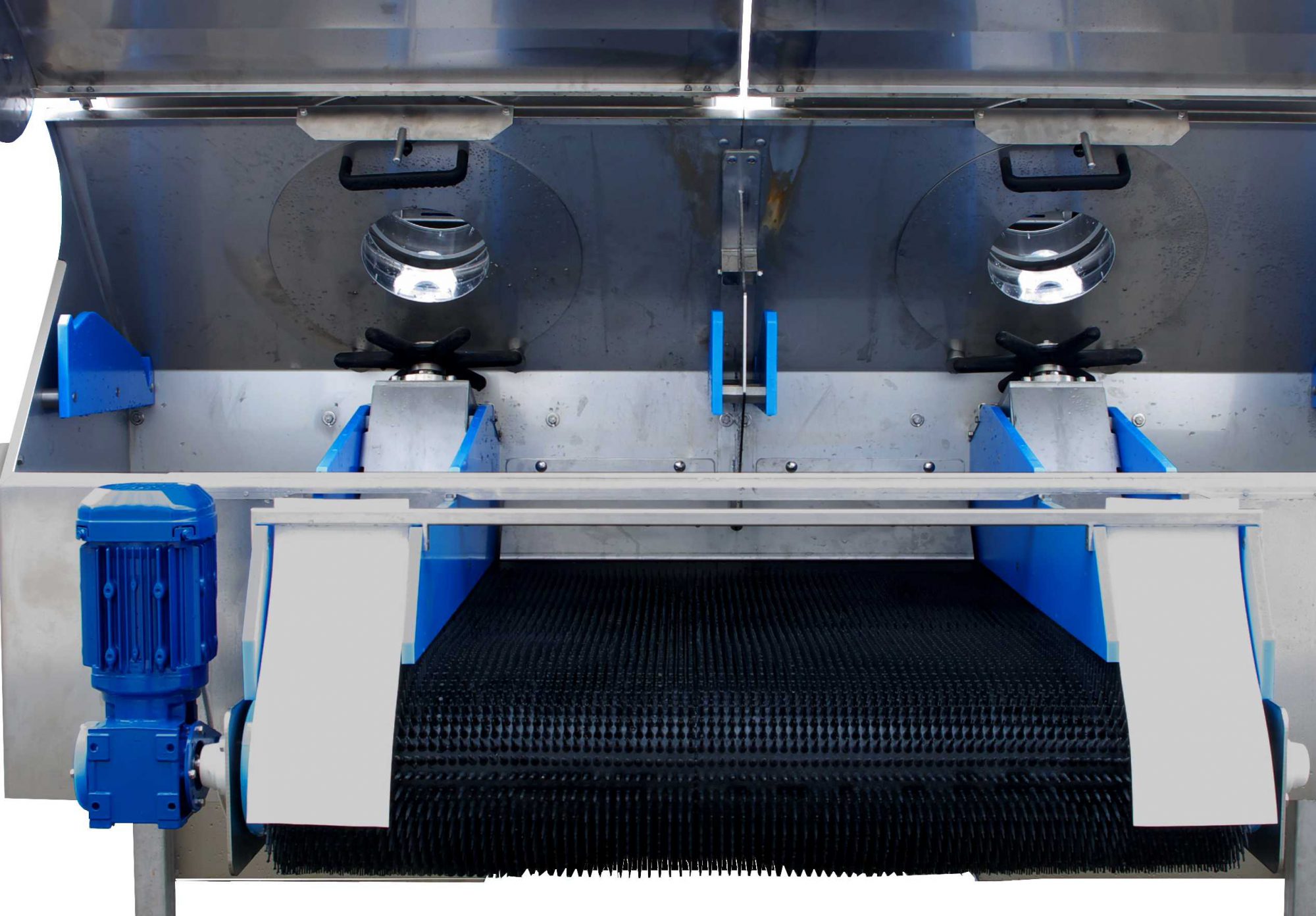

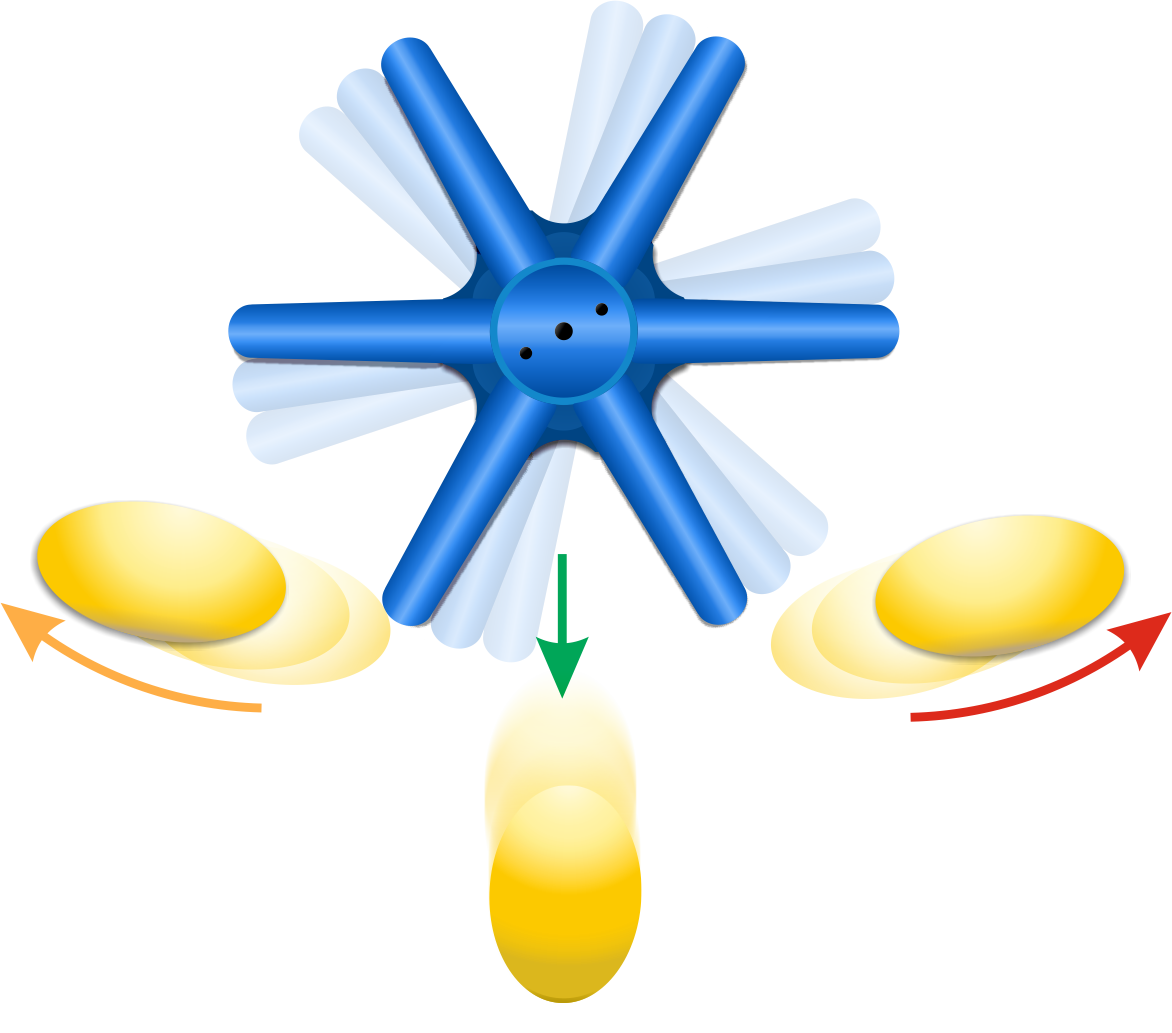

6 rubber fingers

form a rotating star that guides your products from free fall into the assigned sorting compartment.

The rubber-fingered star is moved by an electrically powered ejector for spot-on, fast operation.

This process is internationally patent-protected.

The AGROSELECTOR® twin arcus has separate ejectors for two lines.

At the output of the AGROSELECTOR® twin arcus there are 3 sorting compartments to which you can assign variable sorting qualities.

2 lines

working in parallel and independently of one another give the AGROSELECTOR® twin arcus its unmistakable form.

Several advantages make the AGROSELECTOR® twin arcus a popular sorting machine:

- Soft, rubber “hedgehog belt” at the machine output

- Low noise

- Low energy consumption

- Can be used around the clock

- Safe handling with few hazards

- Long service life with low spare-parts costs

You can download brochures here

► Leaflet AGROSELECTOR twin arcus, leaflet, english